GFRP Rebar

Excellent specific strength

※ Specific Strength : Strength to weight

* Scroll left and right to see the content.

| Material Types | Tensile strength (MPa) |

Density (g/㎤) |

Specific strength (kN·m,/kg) |

|---|---|---|---|

| Low Carbon Steel (AISI 1010) | 365 | 7.87 | 46.4 |

| Stainless steel (304) | 505 | 8 | 63.1 |

| Nylon | 78 | 1.13 | 69 |

| Aluminium alloy (7075-T6) | 572 | 2.81 | 204 |

| Titanium alloy (Beta C) | 1250 | 4.81 | 260 |

| Carbon-epoxy composite | 1240 | 1.58 | 785 |

| Glass fiber | 3400 | 2.6 | 1307 |

| Basalt fiber | 4840 | 2.7 | 1790 |

| Carbon fiber (AS4) | 4300 | 1.75 | 2457 |

| Kevlar | 3620 | 1.44 | 2514 |

▶ About 1/4 the weight of steel rebar

Temperature expansion and temperature transition

※ Similar coefficient of thermal expansion to concrete

* Scroll left and right to see the content.

| Direction | Temperature expansion coefficient (x10-6/℃) | ||||

|---|---|---|---|---|---|

| Steel | GFRP (Glass) | CFRP (Carbon) | AFRP (Alamid) | Concrete | |

| Longitudinal direction | 11.7 | 6.0~10.0 | -9.0~0.0 | -6.0~-2.0 | 7.2~10.8 |

▶ Excellent compared to steel rebar

* Scroll left and right to see the content.

| Steel | GFRP | |

|---|---|---|

| Thermal conductivity | 46 W/mk | 0.35 W/mk |

| Modulus of elasticity | 200 GPa | 50 GPa |

▶ Excellent insulation performance with low thermal conductivity

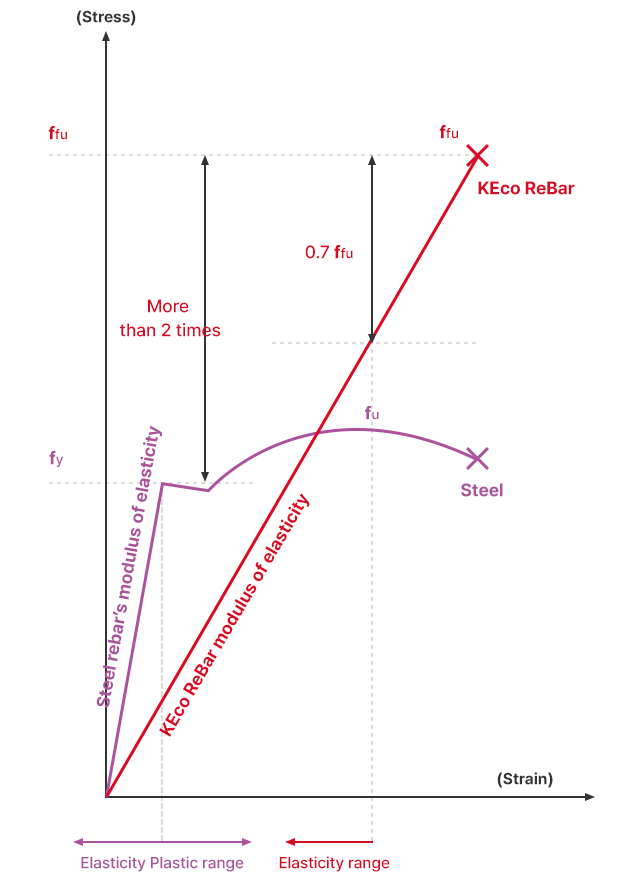

Mechanical properties

▶ Linear stress-strain operation

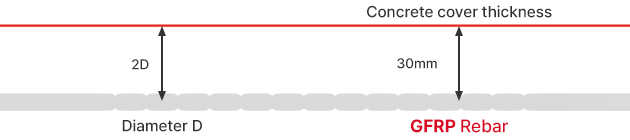

Minimum cover thickness of GFRP reinforcement

▶ Reduction in coating thickness compared to rebar due to corrosion resistance

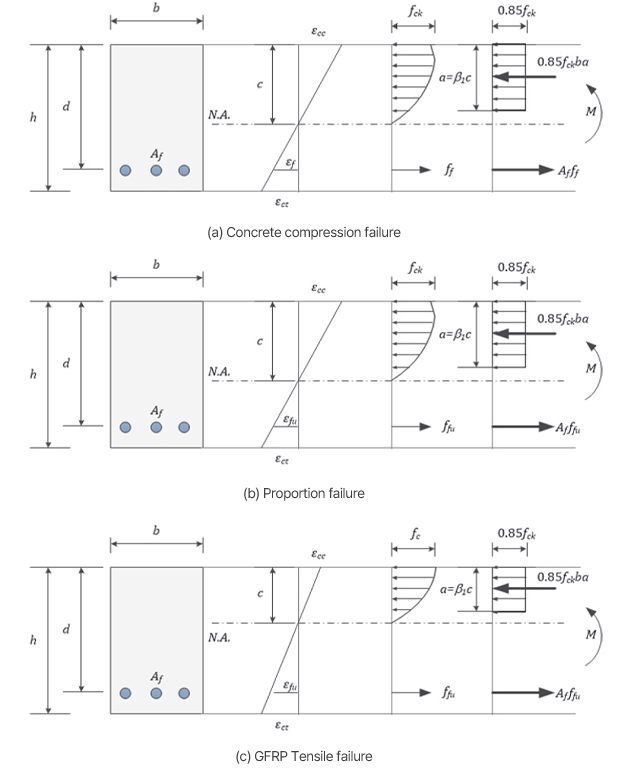

Design of GFRP member

▶ Stress distribution is approximated with a rectangular equivalent stress block used for cross-section analysis of reinforced concrete

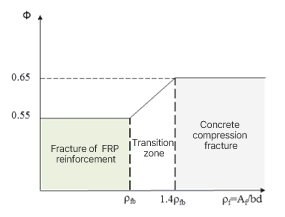

Strength reduction factor

according to reinforcement

ratio

▶ Application of strength

reduction factor in bending

design reflecting failure mode