KEco Soil-Nail is used to improve the stability of natural slopes or artificial slopes caused by excavation, which are at high risk of collapse.

KEco Soil-Nail uses the same solid / hollow type as KEco Rockbolt, and it is easy to construct and it is possible to build a stable retaining wall by using the ground itself as a wall. In particular, it has been widely commercialized due to its superiority in safety, constructability and quality.

GFRP Soil-Nail Quality Standards

· 2016 Apr Established GFRP rock bolt specification by Korea Highway Corporation

· 2017 Aug Establishment of GFRP rock bolt quality standard by Korea Rail Network Authority and Ministry of Land, Infrastructure and Transport

* Scroll left and right to see the content

| Division | Unit | Quality Standards | Remarks |

|---|---|---|---|

| Tensile Strength | MPa | ≥ 850 | |

| Shear Strength | MPa | ≥ 150 | |

| Glass Fiber Content | % | ≥ 75 | |

| Minimum diameter | mm | ≥ 20 |

KEco Soil-Nail Standard Specification

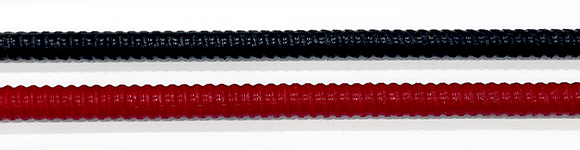

· Solid Type

* Scroll left and right to see the content

| Type NO. | Outer Diameter (mm) |

Ultimate Tensile Strength (MPa) |

Shear Strength (MPa) |

Glass Fiber Content (%) |

|---|---|---|---|---|

| SS-25 | 25 | 850 | ≥ 150 | ≥ 75 |

KEco Soil-Nail Standard Specification

· Hollow Type

* Scroll left and right to see the content

| Type NO. | Outer Diameter (mm) |

Hole Diameter (mm) |

Ultimate Tensile Strength (MPa) | Shear Strength (MPa) |

Glass Fiber Content (%) |

|---|---|---|---|---|---|

| HS-25 | 25 | 12 | 850 | ≥ 150 | ≥ 75 |

| HS-27 | 27 | 12 | 850 |

KEco Soil-Nail / Standard Specification

* Scroll left and right to see the content

| KEco Solid Soil-Nail | KEco Hollow Soil-Nail | |

|---|---|---|

| Materials | GFRP | GFRP |

| Nominal Diameter | D = 23.5mm | D = 27/12(Hole)mm |

| Weight (4m) | 3.88 kg | 3.88 kg |

| The tensile strength | More than 850 MPa | More than 850 MPa |

| Ultimate | 37.0 ton/unit | 32.0 ton/unit |

| Electrical conduction | none | none |

| Durability | Approximately 100 years (corrosion resistance) | Approximately 100 years (corrosion resistance) |

| Constructability |

Lightweight (4kg/4m) for easy to handle · KEco solid rock bolt can be installed by one person · KEco solid rock bolt can be installed by one person · There is almost no dropout due to its own weight when working on the end of the ceiling. · Easy to insert KEco solid rock bolt compared to steel rebar · Difficulty working in the water section |

Lightweight (4kg/4m) for easy to handle · KEco hollow rock bolt can be installed by one person · it Can be injected through a hollow hole without connecting a separate injection tube · It is possible to shorten the construction time and to fill it by 100% · Excellent effect in the work of the water section |

| Stability |

· KEco solid rock bolt can be inserted by humanpower · KEco solid rock bolt can be inserted by humanpower · it is a non-conductive product, it can be used safely even in high-moisture and high-pressure sites. |

Reduced risk factors with lightweight materials and excellent workability · Stable excavation cycle management is possible by reducing worker fatigue and increasing work efficiency · Workers can check the mortar filling status by themselves · 100% filling possible (prevention of falling accidents) · Zero safety accidents by ensuring quality and minimizing risky work |